Different electric cables around your home

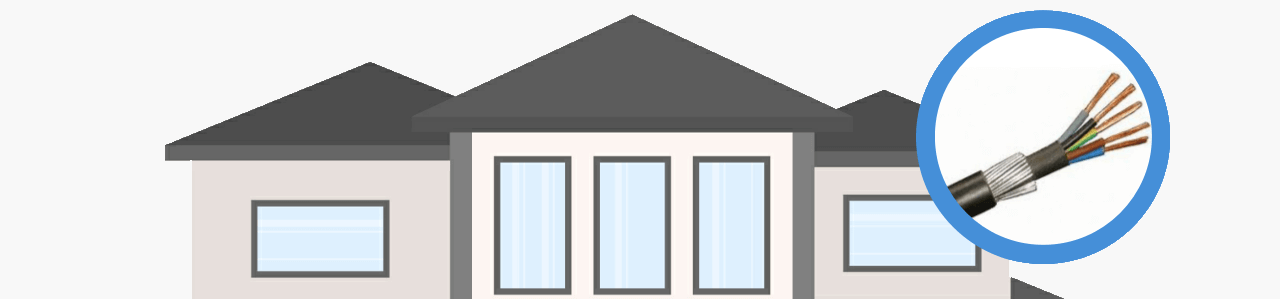

Around your home you will find a variety of electric cables that have all been installed with a different purpose in mind. From everyday electrical items to two way lighting switches, each cable is tailored to a specific use.

Each cable carries an electrical current through your home and its appliances, and each cable has a voltage limit. Within each cable are ‘cores’ which are made up of copper wires, that is coated with insulated plastic and is colour coded for its purpose (neutral, live, earth). These cores are then wrapped together within the cable by another layer of tough, insulated plastic.

It’s important that the correct cables type and size are used, as if not it could cause an electrical fire. For example, if a cable has a max load of 100V and 300V is sent through it, it could burn out and spark a fire in your home.

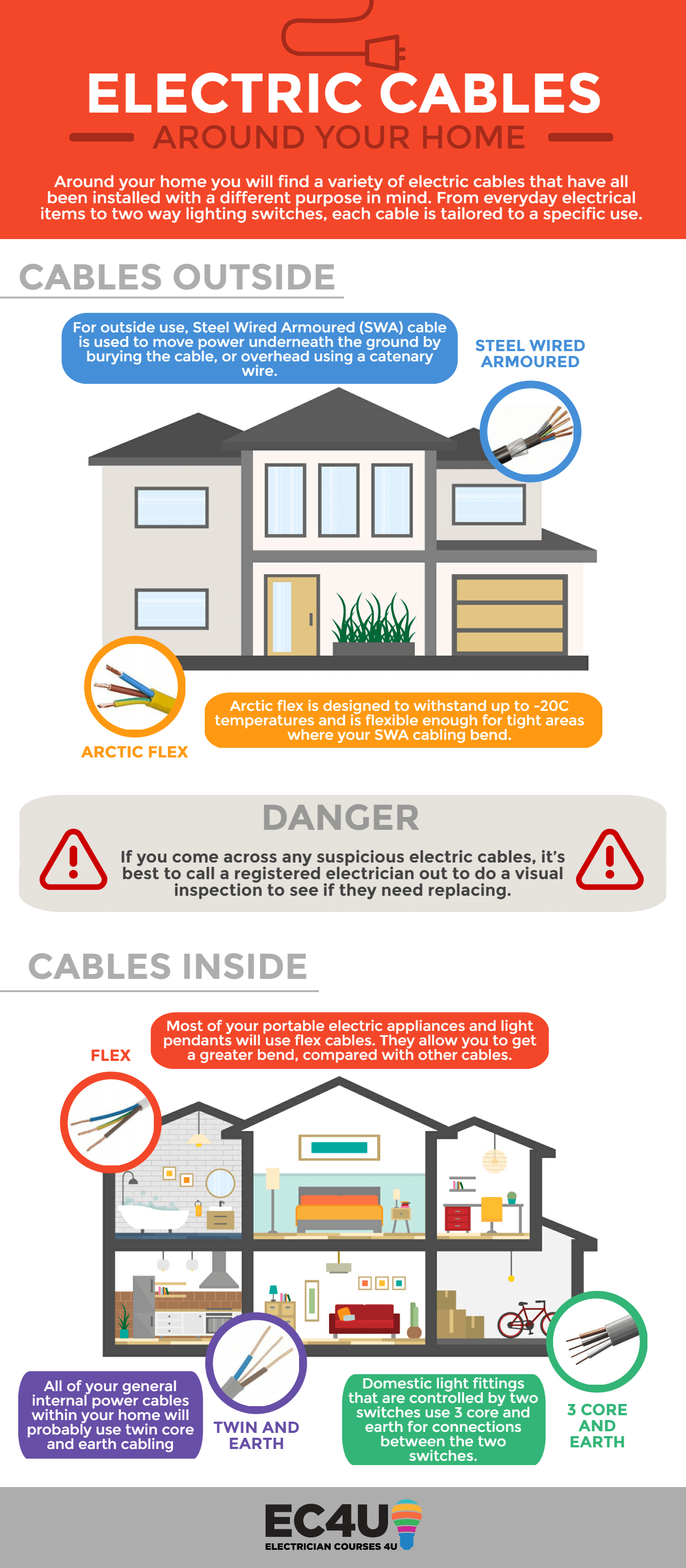

Twin and Earth cables

All of your general internal power cables within your home will probably use twin core and earth cabling. As the name suggests, this type of cabling is formed from two cores, insulated with PVC outer sleeve, and an earth core between the two.

The harmonised colours for this cabling is made up of brown sleeving for the live core and a blue sleeving for the neutral core. The earth core will be clear to see in green and yellow sleeving (but comes bare when you install, you then must cover with insulation sleeve).

You will find twin core and earth cabling used all over your home in a variety of sizes. 2.5mm is commonly used for behind sockets, while 1-1.5mm is most often used for lights (depending on how many lights you have in a circuit).

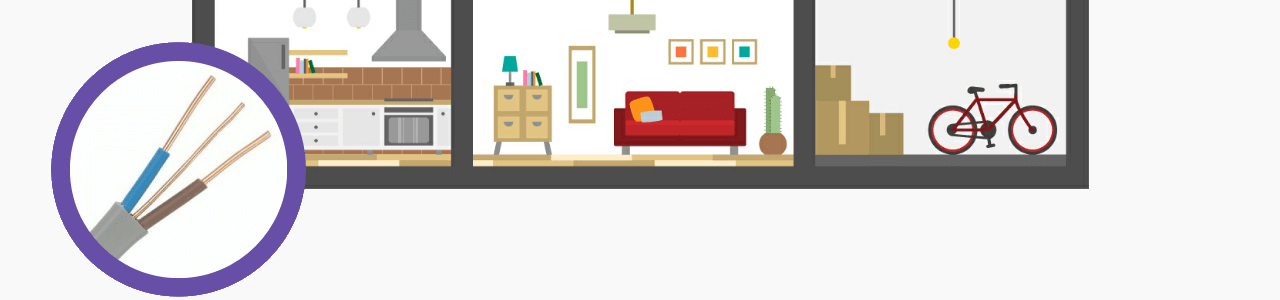

3 Core cables

Domestic light fittings that are controlled by two switches (two way lighting) use 3 core and earth for connections between the two switches. The cable is made up of 3 solid cores, which are individually insulated and wrapped in an outer PVC sleeving. The colours of these cores are brown, black and grey, with a bare earth core (to be insulated with green and yellow sleeving).

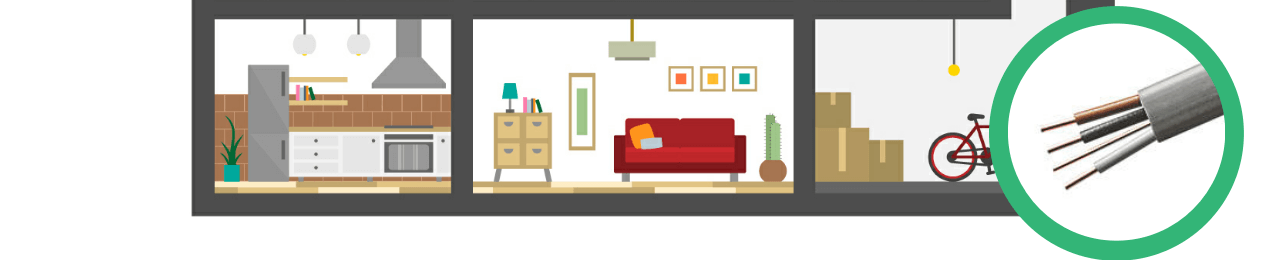

SWA cables

For outside use, Steel Wired Armoured (SWA) cable is used to move power underneath the ground by burying the cable, or overhead using a catenary wire.

The number of cores within the cable can range from two to four, depending on the purpose. The cable is formed up of these inner cores, which are each individually sleeved, then wrapped up together with a layer of plastic sleeving, which is then covered with a layer of protected wire armour, before finishing with a final outer layer.

Due to the multiple layers of protection, the cabling is known to not be as flexible as some other options. If you require a greater flexibility for your connections, then an alternative outside cabling option is Arctic Flex, which is covered below.

Flex cables

Most of your portable electrical appliances and light pendants will use flex cables, as it allows for flexible connections to the power point. The cable is formed in a cross section, normally with 2 or 3 cores insides a PVC outer sleeve coating.

Flex cables allow you to get a greater bend, compared to other cables, and also straighten out with ease. If you’re looking to install something in a tight space outside and require flexibility in the wiring, arctic flex could be what you need.

If you used a standard flex cable outside, it wouldn’t withstand an installation or any movement at temperatures lower than 0°C and would crack under cold weather, which causes issues. Whereas Arctic flex is designed to withstand up to -20°C temperatures, and is ideal for tight areas where your standard exterior armoured cabling just won’t do.

Dangerous electric cable types

If you come across any suspicious electric cables that you believe are out of date, it’s best to call a registered electrician out to do a visual inspection as they could need replacing.

Some old wiring colours and cables to look out for are: rubber insulated, two core (multi strand) covered with an outer lead sheath, and any red and black cables.

These are all clear signs your wiring could need replacing for new cables, as mentioned above. The reason for replacing older cables is that rubber insulation commonly degrades over time and breaks down, increasing your chances of an electrical fault. Any failure of insulation around cables, such as damages or tears, could mean that you are at risk of an electrical house fire.

If you want to know more, read on to find out if your house needs rewiring…

If you would like to learn more on the subject or even how to become an electrician, take a moment to visit our homepage to find out more the UK’s leading practical training provider and the courses we provide!